What is a harsh environment?

A harsh environment generally refers to extreme temperatures, such as extremely hot or cold conditions, that can be challenging for humans to endure. In terms of power supply, a harsh environment can be defined as one where the power supply may be exposed to conditions such as heat, moisture, cosmic rays, and vibration. Thermal management is always a common challenge to the power supply in harsh environments.

Major cooling techniques for power supplies:

There are three main techniques for cooling in power supplies:

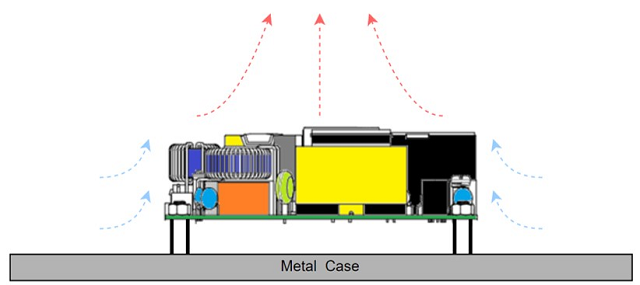

1. Natural convection: When a power supply is heated, the surrounding fluid (such as air) near the heated surface becomes warmer and less dense, causing it to rise. As it rises, cooler fluid from the surroundings replaces it, creating a natural circulation pattern.

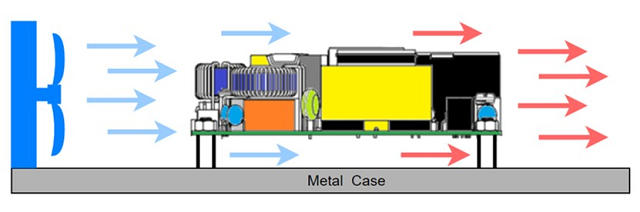

2. Forced air cooling: It is a method of heat transfer that relies on the use of mechanical devices, such as fans, to enhance the natural convection process and increase the rate of heat dissipation from a power supply.

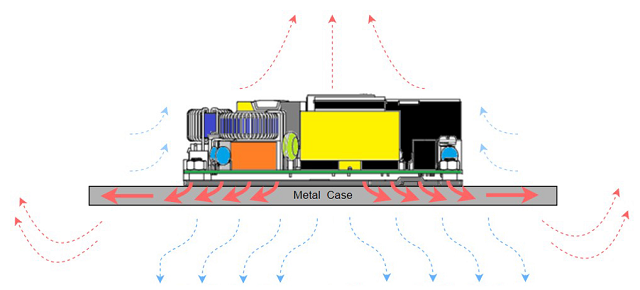

3. Conducted cooling: It is a method of heat transfer that happens through direct physical contact between two objects at different temperatures. Heat generated by components is transferred from the hotter object to the cooler object (metal case) through molecular interactions, without the involvement of fluid motion.

| Pros | Cons | |

| Natural convection | Low/No noise Simple design and construction |

Low power density |

| Forced air cooling | Low cost Greater thermal dissipation capability Excellent power density |

Requirement of external fan Higher maintenance cost Noise and vibrations Low life span and reliability |

| Conducted cooling | High power density Low/No noise Suitable for harsh environment Good thermal dissipation capability High reliability |

A little bit higher cost |

From the table above, it can be seen that conducted cooling would be the most cost-effective and reliable solution, making it ideal for use in harsh environments.

How can a fanless power supply be designed?

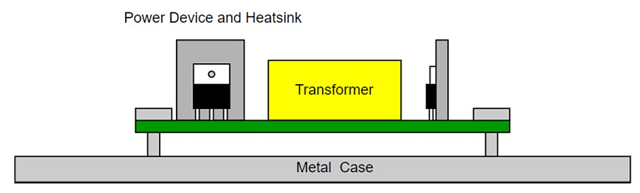

Traditionally, industrial power supplies dissipate heat to on-board heatsinks or a U-channel chassis. The basic structure is shown below as Fig.1. However, the majority of the heat still remains in the power or system, which can have a significant impact on overall system reliability and over temperature protection.

Fig.1 Conventional open-frame power supply structure design

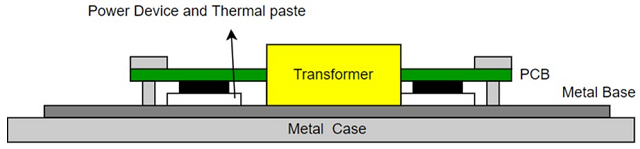

The solution to this problem is to effectively transfer the heat source to the outside of the system. The heat generated by power supply mainly comes from critical components such as power devices, magnetics, and capacitors. By mounting these components directly onto a metal base (baseplate) and attaching them to the metal case of the system, heat can be successfully delivered to the outside. The following Fig.2 shows one of the examples and how the concept works.

Fig.2 Baseplate cooled power supply structure design

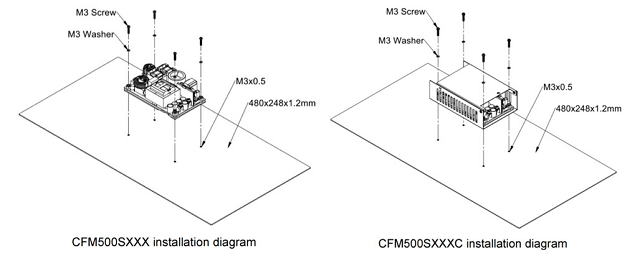

The CFM500S series offers the similar baseplate cooling method, and users can add an extra metal plate with the size of 480mm * 248mm * 1.2mm under the baseplate of the CFM500S to enhance the heat dissipation performance. Please refer to the photos below for installation and more details are specified in the official application note.

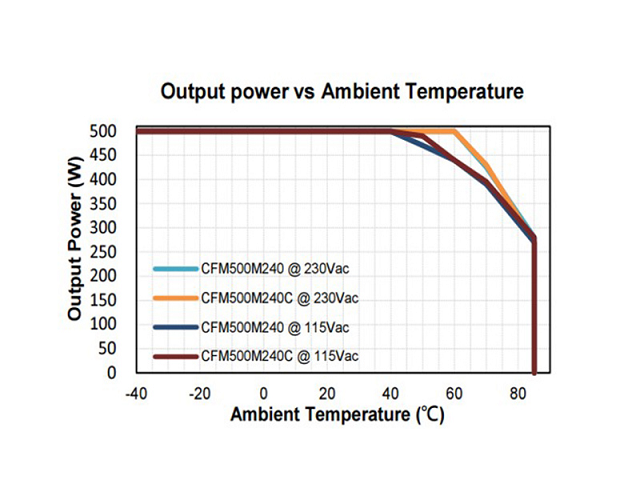

When used with the baseplate cooling solution, the CFM500S series can deliver 500W (full load) without a fan. The power derating curve is shown as below.

Conclusion

Cincon’s AC-DC fanless power solution, which includes baseplate-cooling open-frame, cover, and brick types, is suitable for a variety of systems. The power range starts from 70W to 750W. The baseplate cooling design makes all series in the fanless category achieve higher power density and improves heat dissipation performance under fanless condition and higher ambient temperature. If you are looking for a power supply with all of the aforementioned features, Cincon fanless power supply would be your ideal choice.

Check the product portfolio and contact office@vitecpower.com for more support.

More about Cincon — here.

_______________________________________________________________________________________

ITE/Industrial Fanless Power Supply:

| Model | Type | Input Voltage | Output Voltage | Power |

| CFM130S | Open frame | 80~264Vac | 12V, 18V, 19V, 24V, 36V, 48V |

130W |

| CFM150S | Open frame | 90~264Vac | 12V, 24V, 28V, 36V, 48V |

150W |

| CFM202S | Open frame | 90~264Vac | 12V, 24V, 28V, 36V, 48V, 56V |

200W |

| CFM260S | Open frame | 85~264Vac | 12V, 24V, 36V, 48V | 260W |

| CFM300S | Open frame | 90~264Vac (120~370Vdc) |

12V, 24V, 36V, 48V | 300W |

| CFM400S | Open frame | 80~264Vac | 12V, 18V, 24V, 36V, 48V, 54V |

400W |

| CFM500S | Open frame | 80~264Vac | 12V, 18V, 24V, 36V, 48V |

100W |

| CBM70S | Half-brick | 90~264Vac (120~370Vdc) |

12V, 24V, 36V, 48V | 70W |

| CBM101S | Full-brick | 90~264Vac (120~370Vdc) |

12V, 24V, 28V, 36V, 48V |

100W |

| CBM150S | Full-brick | 90~264Vac (120~370Vdc) |

12V, 24V, 28V, 36V, 48V, 54V |

150W |

| PDF700S | Full-brick | 90~264Vac | 12V, 24V, 28V, 48V, 56V |

700W |

| PFC750 | Half-brick PFC module | 90~264Vac | 390V | 750W |

Medical Fanless Power Supply:

| Model | Type | Input Voltage | Output Voltage | Power |

| CFM130M | Open frame | 80~264Vac | 12V, 18V, 19V, 24V, 36V, 48V |

130W |

| CFM200M | Open frame | 90~264Vac | 12V, 24V, 48V | 200W |

| CFM300M | Open frame | 90~264Vac | 12V, 24V, 36V, 48V, | 300W |

| CFM500M | Open frame | 85~264Vac | 12V, 18V, 24V, 36V, 48V |

500W |