Power supply products are used in a wide range of markets, including communications, automotive, industrial, robotics, aviation, medical, railway, maritime, and data centers. In addition to safety standards, power stability, compact size, and high power density requirements, different application environments have varying thermal management needs.

Power supply products are used in a wide range of markets, including communications, automotive, industrial, robotics, aviation, medical, railway, maritime, and data centers. In addition to safety standards, power stability, compact size, and high power density requirements, different application environments have varying thermal management needs.

Cincon’s customers are spread across the globe, and different markets have different operating voltages, temperatures, and environments. It is crucial to ensure power stability and reliability, as exceeding design rules and application conditions can adversely affect the lifespan and reliability of end equipment.

Regarding thermal management, Cincon provides derating curve information in product specifications and relevant application notes with installation guidelines. Additionally, Cincon offers practical application technical articles that align more closely with actual customer usage. This time, application and test data are also provided to end product designers as a reference for thermal management.

Thermal Management for DC/DC Brick:

In the Brick section, as long as the indicated specifications are not exceeded, full load operation is permissible. If the temperature exceeds the specifications, most products have Over Temperature Protection (OTP) to prevent damage from excessive heat.

For example, the CQB60W-110S product datasheet provides the Derating Curve for its corresponding heatsink:

However, with the trend towards miniaturization in various industries, space requirements have become more stringent. In addition to fan size and airflow requirements, there is an increasing demand for rugged, fanless designs in many systems. Cincon has long been committed to high-efficiency, fanless power solutions and has received similar demands from different application markets. By discussing and verifying these requirements with customers, Cincon has overcome numerous thermal challenges, enhancing the competitiveness of the entire system in the market.

Test Example 1: Railway Communication Application with Shared Heatsink

The customer’s actual application needs, height, and heatsink size differ from the standard specifications in the application note. Using two CQB60W-110S12 units, the customer’s requirement was for a shared heatsink with dimensions of 11 cm x 9 cm and a height restriction of less than 1.2 cm.

Due to size limitations and the non-central position of the CQB60W-110S on the heatsink, high thermal conductivity materials were used to conduct heat to the lower temperature areas around the heat source (copper plates were used for this test). This maximized the utilization of the heatsink’s thermal capacity, allowing heat to be dissipated through the fins of the heatsink. The heatsink was not fastened but placed on the two DC Bricks using thermal paste for a more rigorous test.

Test Conditions:

- Vin: 110Vdc

- Po1: 55W, Po2: 35W

- Continuous operation for 8 hours (no OTP), with the heatsink center temperature reaching 95°C at the end of the test.

(The operating case temperature range of CQB60W-110S series is -40℃ to +100℃.)

Due to the high thermal conductivity material, the temperature difference between the heatsink and the center of the CQB60W-110S12 Brick was less than 2°C.

Ambient Temperature: 70℃

*Cincon’s thermal chamber is UL WTDP certified.

CFB750-300S12 DC Brick + Heatsink

Fanless at Ambient Temperature: 20°C, Po approximately 225W.

Test Example 2: Heatsinks x 2 + High Thermal Conductivity Material Test

Application requirement: Fanless, Ambient Temperature: 25°C, Po: 340W.

Two heatsinks of the same size + high thermal conductivity material, not fastened to the CFB750-300S, for a more rigorous test.

| Temperature Chamber |

Measured various points on the heatsink to confirm the temperature differences across the heatsink due to the high thermal conductivity material. |

|

|

In the actual test, due to the uniform thermal conductivity characteristics of the material, the temperature differences across the heatsink were minimal. The test data are as follows:

|

Po: 237W, heatsink center point temperature only 68 – 69°C. |

Po: 340W, heatsink center point temperature approximately 80°C. |

|

|

|

*Cincon’s thermal chamber is UL WTDP certified. |

|

Thermal Management for AC/DC LFM Series:

The LFM Series features power components with a sink-down and semi-potted design, providing a certain degree of dust resistance and better thermal management compared to the CFM bottom-plate cooling. The diagram below shows the Derating Curves for the LFM300S and LFM420S. The application test example is conducted at Ta: 70°C (marked on the original information).

|

LFM300S |

LFM420S |

|

|

|

Derating Curve without External Baseplate |

|

Test Example: LFM300S, 420S Series

◆ Fin-type metal sealed enclosure.

◆ Enclosure dimensions: 35cm length x 25cm width.

◆ Customer requirement: Ambient temperature of 70°C.

◆ Power height restriction: 1 inch (LFM series height is 1 inch).

◆ Input range: 115 – 230Vac.

◆ Testing the maximum output power under these conditions.

Ambient Temperature: 70°C (long-term testing until thermal equilibrium is reached).

|

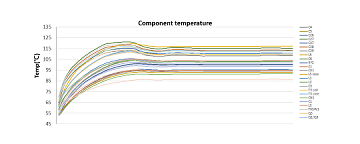

LFM420S120 |

||

| Input Voltage | 115Vac / 60Hz | 230Vac / 50Hz |

| Temperature recording |  |

|

| Output | 11.96V / 23.36A (The average of the last 30 data records.) |

11.96V / 26.45A (The average of the last 30 data records.) |

| Output last record | 11.96V / 23.31A | 11.96 / 26.4A |

| Po | ≒ 278.7W | ≒ 315.7W |

| *Cincon’s thermal chamber is UL WTDP certified. | ||

|

LFM300S120 |

||

| Input Voltage | 115Vac / 60Hz | 230Vac / 50Hz |

| Temperature recording |  |

|

| Output | 12.08V / 14.9A (The average of the last 30 data records.) |

12.06V / 16.8A (The average of the last 30 data records.) |

| Output last record | 12.0V / 14.96A | 12.0V / 16.8A |

| Po | ≒ 180W | ≒ 201W |

| *Cincon’s thermal chamber is UL WTDP certified. | ||

Conclusion:

With the market trend towards miniaturization of end products, designers have higher requirements for power supply size, power density, and operating temperature specifications. Meeting the demand for fanless operation while providing stable and reliable power quality is a continuous optimization goal for Cincon as a power supply design expert. Partners also share many experiences and real-world applications of products in different markets. In the future, Cincon will continue to launch more products that meet market demands, making it easier for end product designers to operate and design their products.

Contact for more support:office@vitecpower.com