Successful Applications

Active EMI Input Filters for PICMG® 3.0 Compliant AdvancedTCA Applications

The AdvancedTCA (or ATCA) standard that was adopted in 2001, established new power requirements with the intent to improve system reliability. Picor develops products that align with the PICMG ® 3.0 Standards.

One example of an ATCA application that Picor is design into is serial rapid I/O for a 10 Gps hub and an advanced mezzanine carrier blade; power is –48 V (36 – 75 V) and about 210 W fully configured. The power requirement calls for independent DC-DC and filtering on each blade with the goal of increasing overall system reliability. QPI active EMI filters provide conducted common-mode and differential-mode attenuation from 150 kHz to 30 MHz (CISPR22 range). The proprietary active filtering circuit provides superior attenuation at low frequencies intended to support EN Class B limits, including PICMG ® 3.0 for ATCA boards.

ATCA blades, with as little as 140 in 2 of available board area, can easily become overcrowded. An active EMI input filter is less than half the size of most passive solutions. For a $12,000 ATCA blade, for example, a QPI filter saves about $85 worth of PCB area. Integrating the EMI filter with hot swap saves even more space, giving designers more room for FPGAs and ASICs.

V•I Chip long-life powertrain for high-performance projectors

Modern projector technologies are much more versatile than old slide projectors, enabling the display of images, video, and even data with high clarity, brightness and even portability. Liquid Crystal Display projection technology, for example, has contrast ratios in the range of 3000 to 1. This technology uses three LCD panels as prisms

to create full color.

The trend in the mobile projection market is toward smaller, yet more powerful projectors. One Vicor customer leveraged the small package size and high efficiency of our V•I Chip components to power the LEDs in their compact, advanced projectors designed for applications, such as high resolution imaging and motion simulation.

In the customer’s design, a discrete PFC AC-DC front end provided a nominal 384 Vdc to two 384 Vin – 48 Vout BCM bus converters in parallel. The 48 V bus enabled the customer to reduce line loss and to use PRM regulator and VTM current multiplier combinations at 200 W each to set up the three different voltage rails for red, green and blue LEDs respectively. The V•I Chip modules provided tight load regulation for Vout and very fast transient response for pulsed loads.

Automation is the use of control systems (such as numerical control, programmable logic control, and other industrial control systems), in concert with other applications of information technology (such as computer-aided technologies [CAD, CAM, CAx]), to control industrial machinery and processes, reducing the need for human intervention. In the scope of industrialization, automation is a step beyond mechanization. Whereas mechanization provided human operators with machinery to assist them with the physical requirements of work, automation greatly reduces the need for human sensory and mental requirements as well. Processes and systems can also be automated.

Our customer is a provider of ― among other products and services ― vertically integrated electronics manufacturing solutions. This application uses a ruggedized embedded computer for an industrial automation system, which is ultimately used as part of a protection system for a nuclear power plant.

FlatPAC-EN is a rugged, EN-compliant, autoranging AC-DC switcher that meets MIL-STD-810E requirements for vibration. One additional important requirement for the power solution was to satisfy the harmonic current provisions of EN61000-3-2. For the last few years, compliance to EN61000-3-2 has been required in order to do business within the European Economic Community. FlatPAC does, in fact , comply with harmonic current limits per EN61000-3-2, and further, also ― valuable for this application ― meets Electrical Fast Transient/Burst per EN61000-4-4 and Surge Immunity per EN61000-4-4. For conducted EMI, the FlatPAC also conforms with FCC Class A and B and EN55022, Class A and B.

Designers of power systems for data centers, or other equipment targeting 99.999 % system availability, are able to achieve very high system reliability by introducing redundancy and fault tolerance to the power architecture. In order to make the system fault tolerant, protection circuitry such as ORing and load disconnect functions needs to be added at each power node that could experience a fault. The use of ORing diodes ― which have a constant forward voltage drop ― introduces undesirable power losses and thermal management challenges. MOSFETs ― which have a much smaller internal resistance called RDS(on) ― have substantially lower conduction losses, and are generally much smaller size while reducing the need for excessive thermal management overhead.

When selecting fault protection solutions an engineer needs to consider the speed, efficiency, and size of the device as well as any thermal management considerations. Efficiency and thermal considerations become more critical if current levels are high.

In an application such as a data center, a power designer usually needs to be able to convert from a high voltage, beginning from a power-factor-corrected AC source, and down-convert in multiple stages, eventually getting down to 1.x volts at the load (for the processor). Picor ORing and load disconnect switch solutions can be deployed in the power system beginning at the 48 V conversion node, and then for any lower voltage node down to the 1.x V load.

Picor Cool-ORing™ and Cool-Switch™ solutions are available as both discrete high-speed controller ICs and as full-function active ORing solutions. Full-function solutions combine the high-speed controller with low on-state resistance MOSFETs in very high-density 5 mm x 7 mm or 7 mm x 8mm thermally enhanced LGA packages. Both solutions offer very fast dynamic response, typically within 160 ns to a system level power source fault condition. The full function solutions are extremely small, high density, and provide very low power dissipation with typical on-state resistances between 1.5 mΩ and 8.5 mΩ.

A router is a networking device whose software and hardware are usually tailored to the tasks of routing and forwarding information. The best example of a router application is the internet where information is directed to various paths by routers. Routers are composed of a buffer for storing data packets and one or more interface cards for routing data packets and a processing engine. Edge routers provide authenticated access to faster, more efficient backbone and core networks. The trend is to make the edge device smarter and the core device(s) „dumb and fast“, so edge routers often include Quality of Service (QoS) and multi-service functions to manage different types of traffic.

Designers of multifunction edge routers, or any other high end communications network equipment, will often select components based on performance and/or space savings, the space savings in turn allows them to add more functionality. Picor Active filters provide both the higher performance through better noise attenuation as well as a space savings. Our customer had been designing line cards for a next generation edge router and the design was becoming space constrained. The new platform needed to free up space for more FPGAs and ASICs. One area that they felt they could recover some board space is in power system. The company already had a preferred DC-DC vendor that they wanted to maintain, so any changes they made had to be compatible with that device. The power bus was -48 V at 150 W. The customer evaluated a Picor QPI filter and found that the filter allowed them to pass EMI with sufficient margin using their preferred DC-DC converter; and more importantly for the designer, the filter was smaller than the legacy solution. The filter was designed-in and is now being considered for use in future designs.

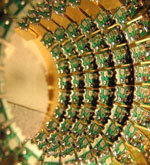

Quantum computing, a new kind of computing, is not likely to replace digital computers in the foreseeable future. Instead of using two states, 0 and 1, on or off, the quantum computer can use both 0 and 1 at the same time, and all points in between, whatever that means. And instead of performing one calculation at a time, the quantum computer can perform many calculations at once. Calculations using quantum bits (qubits) have been accomplished, although the number of qubits involved to date have been quite small. The achievable performance of quantum computers is predicted to be astronomical, far in excess of today’s supercomputers, that is, in the millions of times more powerful. An obvious application for such a computer would be cryptography, enciphering and deciphering of messages. The point has been made that if one of these computers existed today, everything on the Internet would be open to attack or access.

The Vicor customer is working to develop such a machine, and has achieved some success, in three-digit qubits. Their approach uses superconducting electronics for their chip, which operates at ultra-low temperatures in a magnetic vacuum. Room-temperature electronics drive the analog, digital, and power lines for the chip. The electronics must be very low noise in order for it to not disturb the quantum calculation. A Vicor PowerBank AC-DC power supply is used to power the room-temperature electronics.

The PowerBank supply meets the conducted noise requirements of EN55022, Class A from 150 kHz to 30 MHz. It has an input voltage range of 90 – 264 Vac and has six outputs of 4.5, 4,5, 6, 6, 6, 6; total power is 1,500 W.

A rugged ruggedized computer is a computer specifically designed to reliably operate in harsh usage environments and conditions, such as strong vibrations, extreme temperatures and wet or dusty conditions. They are designed from inception for the type of rough use typified by these conditions; commercial units upgraded for this purpose make poor substitutes. Rugged computers can be of many forms including stand-alone bench or desk top units, rackmount systems, laptops, PDAs, wearable systems, and designs specific to the intended installation.

While in the process of redesigning and updating products, a manufacturer of ruggedized PCs for the oil and gas, and military industries determined that they needed power supplies with more power than the previous designs. These highly-engineered PCs are used for automation, as a user interface, and as a command and control center at the point of attack. All of their computers feature fully sealed enclosures and efficient interior-to-exterior cooling channels and heat fins.

In addition to more power, the driving factors for new designs were efficiency, cost, and size. The supply had a 300 V input and three outputs. The total power was 250 W, divided among the three outputs: 12 V at 50W, 3.3 V at 100 W, and 5 V at 100 W. The solution consisted of one VI-ARM with a hold-up capacitor, one Mini for the 3.3 V output, and one Micro each for the 5 V and 12 V outputs.

An important requirement was that the solution had to be potted. Vicor’s proprietary spin fill process assures complete void free encapsulation, making these converters suitable for the harshest environments, perfect for this application.